-

No. 34 Xiayaopo, Bopu, Wuchuan City

PVC Shoe Soles Guide: Durability vs Comfort Analysis

Abstract:

PVC soles are popular in the footwear industry with high cost-effectiveness and design freedom, and have become the darling of fashionable and affordable shoes. Its excellent wear resistance and grip provide reliable safety guarantees, but the hard foot feel and severe lack of breathability constitute a significant comfort shortcoming. This article deeply analyzes the characteristics of PVC soles through six dimensions, revealing its essence that it is difficult to have both economy and comfort, and provides a scientific reference for rational consumption.

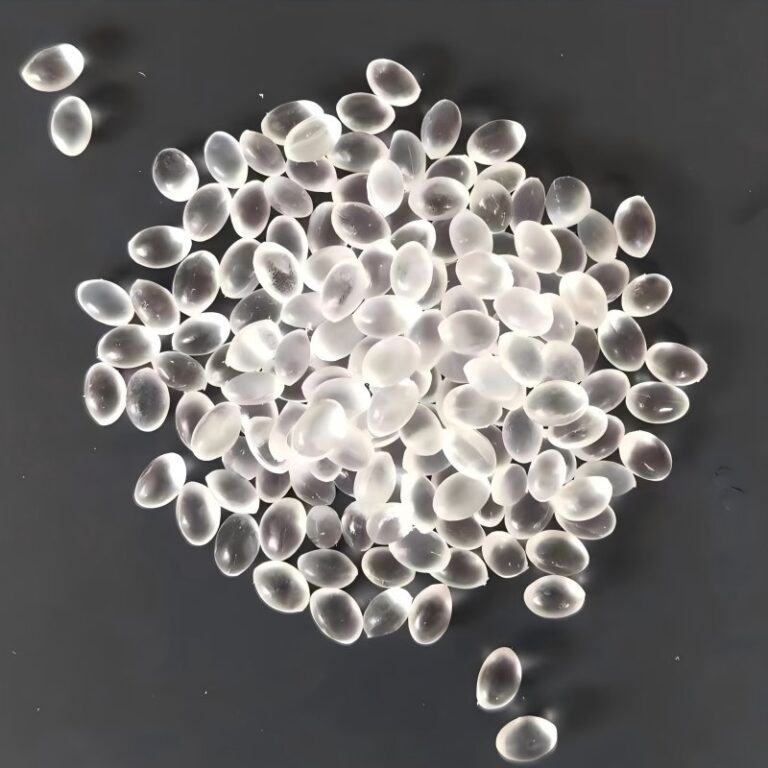

PVC (polyvinyl chloride) soles have firmly occupied a place in the global footwear market with their distinctive double-sided characteristics. In-depth understanding of its technical characteristics and performance boundaries is the key to balancing consumer choices and wearing experience.

1. Economy: The core driving force of the affordable market

The cost of PVC resin raw materials is significantly lower than that of rubber, TPU and other materials (Source: Grand View Research Footwear Market Report). Its efficient injection molding process greatly compresses the production cycle and energy consumption, making the finished shoes have outstanding price competitiveness. Consumers can get colorful and unique shoes at a price far lower than that of natural rubber-soled shoes.

2. Design freedom: the magician of visual innovation

PVC has excellent fluidity after melting, and can accurately replicate complex mold textures. Highly compatible colorants support the deployment of any bright colors or transparent effects, satisfying the pursuit of visual impact in fast fashion. From imitation crocodile leather patterns to fluorescent transparent thick soles, PVC gives designers almost unlimited creative space (application examples can refer to ASOS or Zara’s PVC-soled shoes of the season).

3. Wear-resistant and durable: a tough shield against wear

PVC has a tight molecular structure and high surface hardness (Shore hardness is generally >80), giving it excellent scratch resistance. Laboratory roller tests show that its wear resistance index can reach more than 1.5 times that of ordinary EVA materials. In the scene of walking on dry hard roads, the life of PVC soles is significantly superior (data support: SATRA TM174 sole wear test standard).

4. Grip safety: a reliable partner in slippery environments

Dense PVC material can produce strong molecular adsorption when in contact with the ground. The freedom of sole pattern design enables it to optimize drainage and anti-skid grooves in a targeted manner, providing reliable anti-skid properties on smooth surfaces such as tiles and marble (anti-skid coefficient>0.4, in line with EU EN ISO 13287 safety standards). PVC safety shoes are often specified for special scenes such as construction sites or catering kitchens.

5. Comfortable flaws: difficult-to-solve physical limitations

PVC is essentially a hard plastic with a lack of elasticity in its molecular chains. Dynamic mechanical analysis shows that its energy feedback rate is less than 15%, far inferior to rubber (60%) or foam materials (70%+). When walking for a long time, insufficient cushioning can easily lead to stress concentration in the plantar fascia, causing fatigue or pain (the American Podiatric Medical Association APMA has issued a number of clinical guidelines warning of the risks of hard-soled shoes).

6. Breathability dilemma: destroyer of foot microclimate

PVC is a completely non-porous material with a water vapor transmission rate (MVTR) of almost zero. Experiments show that the humidity in the shoe cavity can reach more than 85% after wearing for 2 hours, and the temperature rises by 5-8℃. The hot and humid environment becomes a breeding ground for fungi, significantly increasing the risk of skin diseases such as tinea pedis and sweat herpes (for clinical research, see the Journal of the American Podiatric Medical Association).

Summary:

PVC soles are like a savvy “economical and affordable ally”, achieving dazzling design and basic protection at a low price, and showing their advantages in short-term commuting, fashion wear and other scenes. However, the nature of its material locks the upper limit of comfort – the hard base and the suffocating wrapping constitute an irreconcilable physical contradiction. Consumers need to be aware that when pursuing all-weather comfort and a healthy foot environment, investing in breathable and elastic materials (such as natural rubber and technological foam materials) is a more rational choice. The value of shoes lies not only in decorating the feet, but also in the ability to support us to walk steadily in the world. In the game between cost and health, wise choices are better than blind cheapness.