-

No. 34 Xiayaopo, Bopu, Wuchuan City

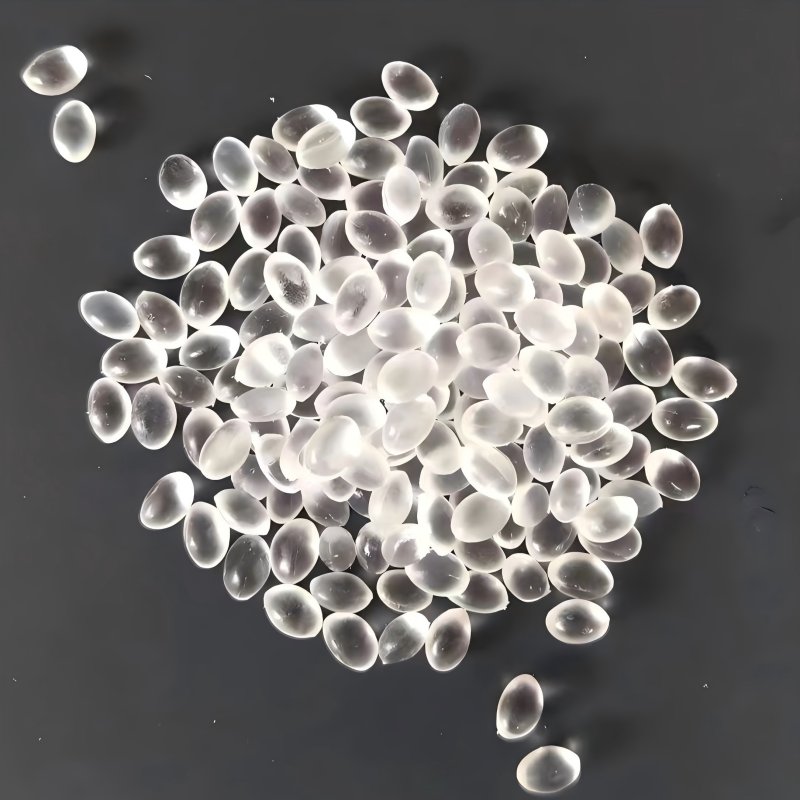

EVA material: the lightweight and functional revolution

A high molecular polymer made of ethylene and vinyl acetate is quietly driving the industrial upgrade from sports equipment to solar panels.

The moment you put on your sneakers in the morning, you may have come into close contact with EVA materials. The light rebound feeling of the sole is the magic of ethylene-vinyl acetate copolymer (EVA). As the fourth largest ethylene copolymer in the world, EVA achieves a perfect balance between softness, elasticity and processing performance by flexibly regulating the content of vinyl acetate (VA) in its molecular chain (5%-40%).

While the global market is expanding at a compound annual growth rate of 7.6%, China is leading the global demand with an annual consumption of 1.86 million tons. From the soles of sports shoes under your feet to the encapsulation film on photovoltaic panels, this seemingly ordinary polymer is becoming an invisible bridge connecting daily life with cutting-edge technology.

Material Essence: Chemical Identity and Formation of EVA

EVA (ethylene-vinyl acetate copolymer) is copolymerized by ethylene monomer and vinyl acetate monomer under high temperature and high pressure. It is the fourth largest ethylene copolymer after HDPE, LDPE and LLDPE. The content of vinyl acetate (VA) in its molecular structure is the key variable that determines the properties of the material: When the VA content is less than 40%, it is a resin, which is suitable for film and injection molding; 40%-70% forms an elastomer, which is used in fields such as footwear; 75%-95% becomes an emulsion state.

The production process mainly adopts the autoclave method or the tubular method, and the VA unit is embedded by precisely controlling the reaction temperature, pressure and catalyst ratio. This molecular design gives EVA a unique performance adjustability – increasing the VA content can improve the material’s flexibility and transparency, while reducing the VA ratio can enhance rigidity and heat resistance.

It is this “molecular building block”-like flexibility that has enabled EVA to continue to expand its application boundaries since its first synthesis by ICI in 1938, becoming a versatile player in the field of polymer materials.

Core characteristics analysis: dual-sided performance

EVA material exhibits a series of excellent physical properties:

- Lightweight: The density is only about 0.93g/cm³, which is 30%-50% lighter than traditional rubber, and is the key to reducing the load on sports shoes

- High elasticity and cushioning: The flexibility of the molecular chain provides excellent rebound, and the energy absorption rate is as high as 60%-70%, which effectively alleviates the impact of walking

- Processing adaptability: The melting point is about 80℃, which is easy to be injected, foamed and hot-pressed, and supports complex sole structure design

These advantages make EVA the mainstream choice in the footwear market. About 65% of sports shoes in the world use EVA midsoles. This material also has application limitations:

- Temperature sensitivity: It is easy to soften and deform at high temperature (>70℃), and harden and brittle at low temperature (<0℃), which affects its use in extreme environments

- Mechanical strength limitations: The tear strength is only 3-5MPa, and it is easy to be pierced by sharp objects; permanent deformation may occur after repeated compression

- Environmental aging problems: UV radiation causes yellowing and hardening, and anti-UV additives need to be added for outdoor use

These defects have prompted the industry to develop EVA composite materials, such as blending with rubber to improve wear resistance, or adding mineral fillers to enhance dimensional stability.

Application territory: From feet to clouds

Shoe material field

The application of EVA in the shoe industry is a classic case. Its advantages of lightweight and high elasticity are brought to the extreme in the midsole of sports shoes: the independent closed-cell structure of foamed EVA can form an air cushion effect, and the anti-slip friction coefficient of 0.4-0.7 can be achieved with the molded pattern. The early air cushions of Nike Air series and Crocs hole shoes are all based on EVA as the core material. Currently, high-end sports shoes use a three-layer composite structure – the upper layer of dense EVA provides support, the middle layer of foamed EVA provides shock absorption, and the bottom layer of rubber enhances wear resistance.

New Energy Packaging

The explosion of the photovoltaic industry has enabled EVA to achieve a gorgeous turn. As a photovoltaic film substrate, its light transmittance is >91%, and its weather resistance guarantees a 25-year life of the component. It currently accounts for more than 50% of the packaging material share. Although China’s EVA photovoltaic material production capacity has increased rapidly (an additional 900,000 tons in 2023), high-end materials still need to be imported from South Korea’s LG and other products.

Multifunctional film materials

EVA shows amazing adaptability in the field of film materials:

- Agricultural shed film: Adding 8%-15% VA to EVA improves the durability of anti-fog droplets, extending from 2 months of ordinary PE film to more than 4 months

- Packaging film: Films with 5%-10% VA content have both toughness and transparency, and are used for aseptic packaging of food

- Cable sheath: Flame-retardant formulas with 12%-24% VA content meet halogen-free cable standards

Market landscape: Capacity competition driven by demand

The global EVA market is experiencing structural growth, the market size will reach 59 billion yuan in 2023, and it is expected to exceed 93.9 billion yuan in 2029, with an average annual growth rate of 7.6%. The Chinese market presents the characteristics of “two-wheel drive”: the annual growth of 30% in the photovoltaic industry has brought a gap in high-end materials, while traditional fields such as shoe materials have maintained a stable growth of 6.9%.

In terms of capacity layout, Chinese companies are catching up quickly:

- Sinopec leads: its bases such as Yangzi-BASF and Yanshan Petrochemical account for more than 60% of the total capacity

- Private enterprises join: New players such as Lianhong New Materials (120,000 tons) and Zhejiang Petrochemical (300,000 tons) join

- The capacity is expected to reach 3.35 million tons in 2024, but 440,000 tons of high-end materials will still need to be imported

Price fluctuations highlight industry contradictions: In 2023, the peak price of photovoltaic-grade EVA exceeded 28,000 yuan/ton, and ordinary shoe materials were about 16,000 yuan/ton. The price difference reflects technical barriers. This pattern is stimulating companies such as Wanhua Chemical to accelerate the research and development of photovoltaic materials and promote the process of import substitution.

Future track: the intersection of innovation and sustainability

Technology breakthrough direction

Functional upgrade becomes the focus of research and development:

- Reinforced composite materials: Nano-silica modified EVA improves tear resistance by 50%, meeting the needs of mountaineering shoes

- Intelligent response materials: Temperature-sensitive EVA triggers pore deformation at 35°C, dynamically adjusting the microclimate inside the shoe

- Cross-linking technology: Electron beam irradiation makes EVA form a three-dimensional network, and the heat resistance is increased to 120°C

Environmental transformation

Circular economy pressure drives green innovation:

- Biological-based EVA: Brazil’s Braskem replaces petroleum-based monomers with sugarcane ethylene, reducing carbon footprint by 70%

- Chemical recycling: Japan’s Mitsubishi develops alcoholysis technology, and the recycling rate of discarded soles reaches 90%

- Degradable formula: The Chinese Academy of Sciences team adds PGA to promote photodegradation and reduce microplastic pollution

New application frontier

Material cross-border opens up a growth curve:

- Medical orthopedics: 3D printing customized insoles, combined with antibacterial EVA to effectively prevent diabetic foot

- Architectural acoustics: Foamed EVA sound barriers absorb traffic noise and replace traditional rubber

- New energy batteries: POE modified EVA is used for solid-state battery separators, with a thermal shutdown temperature of 130°C

Photovoltaic panels efficiently convert energy under the scorching sun, sneakers bounce lightly on city streets, and aseptic packaging ensures food safety – these seemingly unrelated scenes are all connected in series by the ethylene and vinyl acetate units in the EVA molecular chain. When China’s production capacity exceeded the 3.35 million tons mark, the technical breakthrough in the field of high-end materials continued.

This material, which was born nearly 90 years ago, is improving its tear strength through nano-modification, reducing carbon emissions through bio-based routes, and opening up new medical application scenarios through intelligent responsive design. From the feet to the cloud, the evolution of EVA confirms a truth: the innovation of basic materials is the most lasting engine of industrial change.