-

No. 34 Xiayaopo, Bopu, Wuchuan City

Non-Slip Slippers Selection: Materials, Patterns & Safety

The update of a national standard is quietly changing the most inconspicuous home safety line under our feet.

A slippery bathroom floor, a piece of soap, a pair of old slippers – these daily elements combined together can lead to catastrophic consequences. According to statistics, about 25 million elderly people over 60 years old in my country are injured by falls every year, of which the probability of falling in the bathroom is as high as 26.6%.

Behind the accidents, there are often neglected problems with the anti-slip performance of slippers. With the update and implementation of the QB/T 4552-2020 “Slippers” national standard, anti-slip has changed from a vague concept to a measurable and executable technical indicator.

1. Standard evolution, anti-slip performance from vague to precise

On April 1, 2021, the QB/T 4552-2020 “Slippers” standard was officially implemented, replacing the old 2013 version of the standard. The biggest change in the new standard is the quantitative requirements for anti-slip performance.

According to the standard, the wet horizontal mode dynamic friction coefficient of bathroom slippers and all slippers with nominal anti-slip function shall not be less than 0.40. This value has become the gold standard for measuring anti-slip performance.

What is the concept of a friction coefficient of 0.40? Professional testing agencies conduct tests by simulating two bathroom environments, wet and detergent-containing. Under extreme conditions of applying detergent, the friction coefficient of most samples is only 0.17-0.75, and only 9 samples are above the safety line of 0.40.

The formulation of this standard is not groundless. International standards such as ASTM F2913-19 and ISO 13287:2019 have established mature anti-slip test methods for footwear, including standard inclined plane method and pendulum test method. The upgrade of national standards marks that my country’s slipper safety specifications are in line with international standards.

2. Material code, molecular structure determines safety factor

The core secret of slippers’ anti-slip performance is hidden in the sole material. At present, mainstream materials can be divided into three categories: PVC, EVA and rubber composite materials, and each material has a different anti-slip logic behind it.

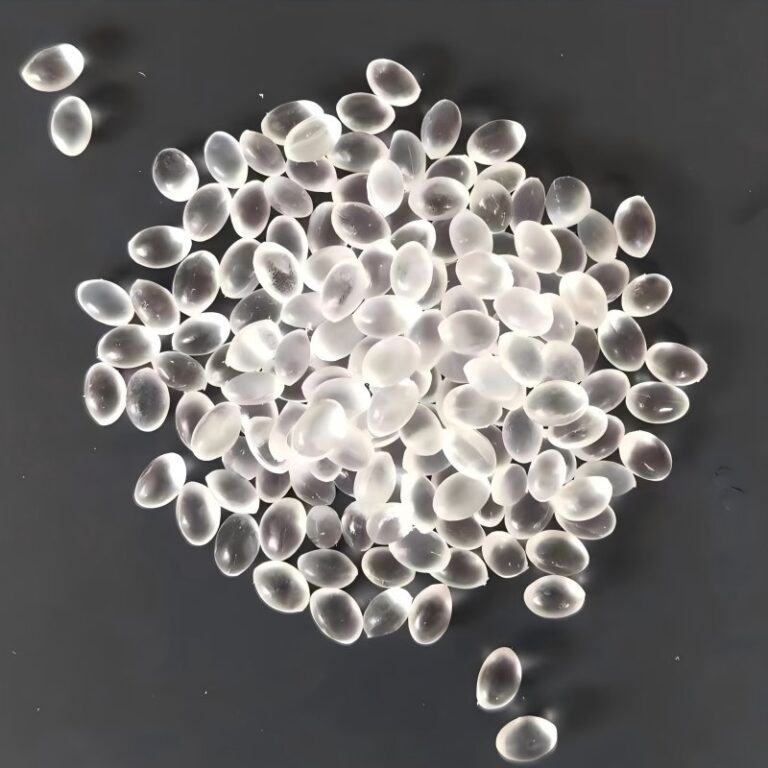

PVC (polyvinyl chloride) slippers use an open-cell foam structure, like countless interconnected small rooms. This structure can produce an adsorption effect when under pressure, improving instantaneous grip. But the open-cell structure has also become a breeding ground for bacteria – the sulfur-containing substances produced by metabolism make PVC slippers notorious.

EVA (ethylene-vinyl acetate copolymer) presents a closed-cell foam structure, and the bubbles are isolated from each other. This material has better ductility and can form more complex anti-slip patterns. Anta’s high-soft elastic cushioning EVA formula adds 1 to 2.5 parts of four-needle zinc oxide whiskers, whose needle length is 3 to 200 microns, which can significantly improve wet anti-slip properties.

Rubber-based composite materials perform well in the field of professional anti-slip. Laboratory data show that samples with large solid rubber-plastic patches perform well in the sole hardness test, with the wear mark length as low as 6.5 mm (the better the wear resistance, the lower the value), which is much better than the 16.5 mm of ordinary foam materials.

3. The mystery of the pattern, micron-level design determines the success or failure of anti-slip

The pattern of the sole is the first line of defense against slipping. Excellent design must meet three functions at the same time: rapid drainage, increased contact area, and creation of adsorption effect.

The Shanghai Consumer Protection Committee found that the depth of the sole pattern must be ≥2mm, the surface roughness (Ra value) must be between 0.5-2.0μm, and the contact area support rate must be ≥60% to provide reliable wet and slip protection.

Innovative design continues to break through the limit of anti-slip:

- Suction cup structure: When the micro suction cups on the sole are squeezed, air is discharged and atmospheric pressure is used to generate additional adhesion

- Composite weaving technology: The patented sole combines the plastic frame with ice silk thread weaving to form wear-resistant and anti-slip edges on the edge

- Multi-directional drainage grooves: The criss-crossing grooves can quickly drain the liquid at the moment of stepping on it, keeping the sole in contact with the ground

Market verification shows that products that can still maintain a friction coefficient of 0.75 in extreme detergent environments generally use multiple annular patterns + micro suction cup composite design on the sole.

4. Market truth, 95% of anti-slip claims are not worthy of the name

Anti-slip is the core selling point of bathroom slippers, but the actual performance is worrying. The 35 bathroom slippers evaluated by the Shanghai Consumer Protection Committee in 2024 reveal the cruel reality:

Only 3 products performed well in wet and detergent-containing environments: TZLDN Lidani men’s home shoes, Paul Frank big mouth monkey women’s sandals and MEEK BOTH sandals.

In the wet friction coefficient test, 26 models met the standard (≥0.40), and 9 models did not meet the standard. In the test simulating the shower gel environment, only 9 models were above the safety line.

Consumers are often misled by the “feeling of stepping on shit” marketing. In fact, too soft soles (Shore hardness type A <50) are more likely to fold and deform, increasing the risk of tripping. Professional tests show that the hardness of the four samples with solid patches is good, while 20 of the 31 samples mainly made of foam materials are judged to be high risk because they are too soft.

5. Professional testing, scientific instruments reveal the truth about safety

The judgment of anti-slip performance requires the support of professional testing equipment. Nationally accredited laboratories mainly obtain objective data through three types of instruments:

Friction coefficient tester (such as FCT-2000) can accurately measure the friction coefficient in the range of 0.01-1.0 with an accuracy of ±0.02. This is the core equipment to verify whether it meets the 0.40 safety line.

Abrasion tester (AT-100) simulates daily wear and measures the length of wear scars after 0-10000 revolutions. The wear scar length of high-quality products should be <10mm, while the anti-slip performance of products with excessive wear will decrease by more than 30%.

Dynamic friction analyzer (DFA-150) tests at a variable speed of 0.1-10m/s and captures instantaneous sliding risks with 1000Hz high-frequency sampling.

Consumers’ simple judgment method: Place the slippers on a 12-degree slope, pour diluted shower gel on them, and test the critical slip angle; or rub the left and right soles relative to each other to feel the resistance – but these methods are far less accurate than professional testing.

6. Life cycle, a safe journey from factory to trash can

The anti-slip performance of slippers is a process of dynamic attenuation. Wear resistance tests show that after 5000 rotations of wear on ordinary EVA soles, the depth of key anti-slip grooves may be reduced by more than 50%.

Main points for use and maintenance:

- Special shoes for special use: Avoid wearing bathroom slippers outdoors to prevent premature wear

- Monthly deep cleaning: Use white wine or white vinegar to clean the gaps to inhibit the reproduction of anaerobic bacteria

- Dry storage: Rinse the slippers after taking a shower and dry them to destroy the moist environment of bacteria

- Wear inspection: Replace them immediately when the depth of the sole grooves is <1mm or there is a local smooth area

Although the national standard does not specify the service life, the test data shows that after 3 months of normal use, the friction coefficient of the key area of the sole may decrease by 30%. It is recommended that families check the anti-slip grooves of slippers once a quarter.

Anti-slip technology for slippers is at the forefront of innovation. Zinc oxide whiskers are added to the EVA formula developed by Anta’s laboratory. This needle-shaped material with a length of only 3 to 200 microns looks like a micro anti-slip spike under a microscope, which increases the wet friction coefficient of the foam sole by 40%.

The implementation of the national standard QB/T 4552-2020 is pushing more companies to transform anti-slip from a marketing tactic to a technical indicator. Next time you buy, ask the customer service: What is the wet dynamic friction coefficient of this slipper?

The answer is over 0.40, which can really withstand the test of wet and slippery ground.